structural development

Healthy, soft, versatile: eco-softfibre, the innovative world novelty from Görlitz

- structural development

- Hits: 3008

Hello!

Some founding and innovation stories from our district are so good that it's just fun to tell them and to keep our fingers crossed that this invention will soon find its way into the whole world.

The one from eco-softfibre is one of those. eco-softfibre produces an ecological soft foam from natural materials.

It can be used as a sound absorber indoors or for upholstery in the furniture and clothing industry. In contrast to conventional foam, polyurethane, eco-softfibre meets all the expectations that one has of a modern material today: it is a recyclable natural product that can be easily processed and is ecologically harmless. It does not emit any toxic, in the worst case carcinogenic fumes - one of the biggest advantages over petroleum-based foam (plastic) materials, which have to be disposed of as hazardous waste. "Hardly anyone is really aware of the health risks of the foam materials that surround us, in cars, in upholstery and mattresses," explains Hr. brave. "Who reads the small print on the instruction leaflet for a mattress, for example, and then lets a new mattress air out in a lonely room for weeks?" he asks rhetorically.

Another convincing argument for the new Görlitz foam: eco-softfibre is made from residues from the leather industry, ie the raw materials required for production are available in huge quantities worldwide.

When our project manager Saskia Brosius told me about the eco-softfibre founding story after a visit to the SIEMENS innovation campus Because the two likeable inventors behind it and their original Görlitz product simply deserve attention!

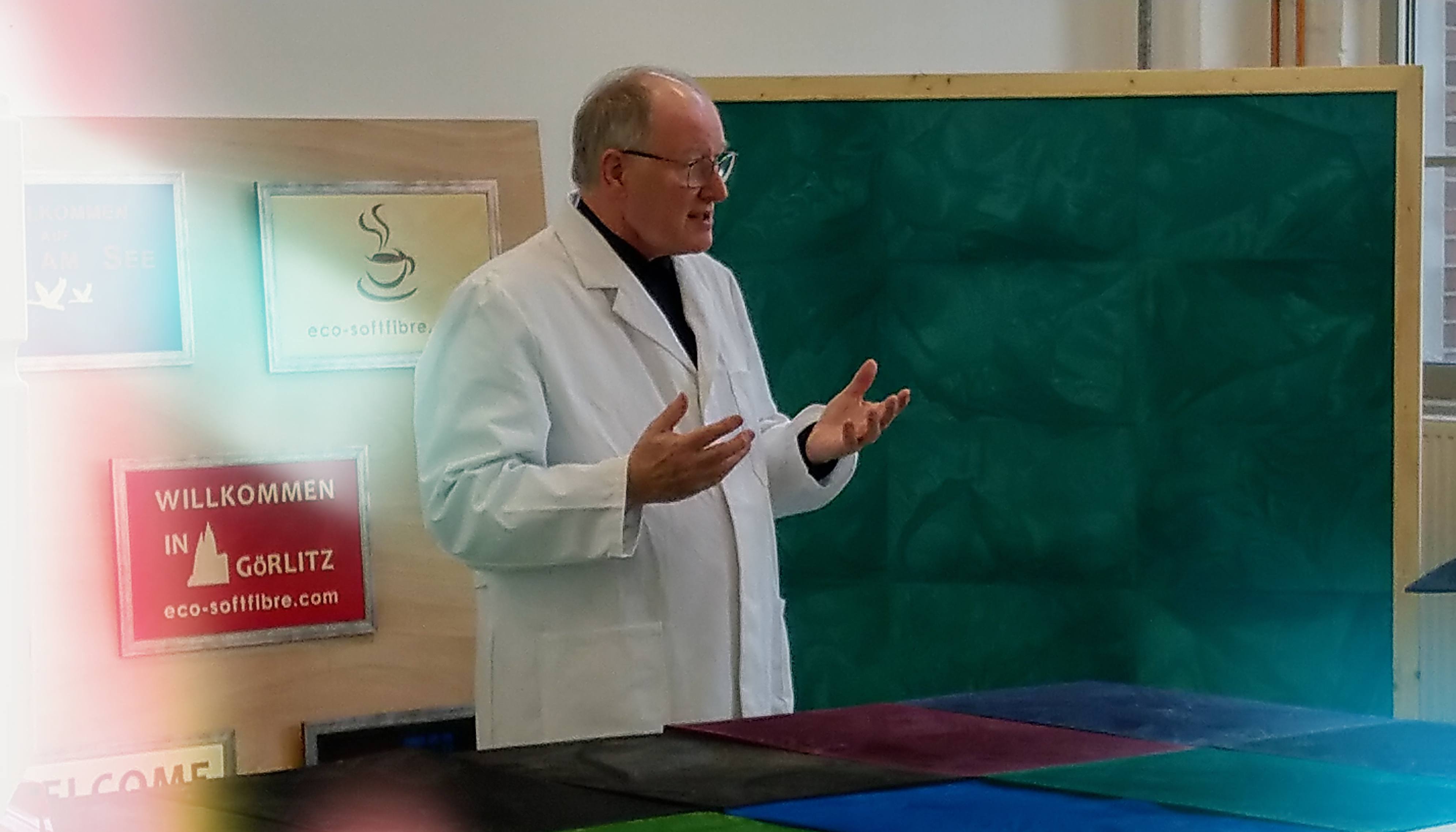

Bernd Wacker, father of eco-softfibre, reports how he became an inventor at just over 50 and immediately afterwards the company founder: "In 2018 I was working as a company coach in Italy. On a tour of a tannery I saw leather shavings, a residual product." He touched the shavings - they felt fluffy and somehow valuable. It seemed too good to throw away. He automatically started to think: what could be done with this material? Six months later, Bernd Wacker was back in the tannery and asked what would be done with these leather shavings. When it said "nothing at all", the electrical engineer, who worked for SIEMENS for many years, started to tinker in the garage at home. After a few attempts, he succeeded in foaming the leather shavings - Bernd Wacker says: "comparable to egg whites" - and using them to create a new, ecologically harmless plastic that can be used in many ways.

The next logical step was to convince his friend Wolfgang Coutandin to start a company together. "I wouldn't have done it alone, I'm very happy about the teamwork with my friend," explains the young entrepreneur.

Done, done: the company was founded in March 2020. The lockdown period was used to set up a technical center and to determine funding opportunities, e.g. from the Saxon development bank, with Christoph Scholze, then innovation manager at SIEMENS. "In addition, we kept groping our way towards the quality that we had in mind," says Wacker, describing the further process. Since January 2021, the company has been "able to deliver" with foam surfaces of up to 200 square meters, as the inventor proudly explains. While he tends to take care of the technical side, his partner works in the field - the two of them now exhibit in showrooms and are currently targeting designers and interior decorators rather than the really big market. The application as a sound absorber for hotels, restaurants and open-plan offices is particularly important to him, but also for newly built apartments, because we humans spend two thirds of our time indoors - and of course we all want a good indoor climate that is not harmful to health. However, eco-Softfibre is still quite expensive, but Bernd Wacker is trying to change that: through larger production. Because the manufacture of the innovative material is still expensive, there is still "a lot of room for scaling".

Currently there are many discussions to bring about the financing for a larger production. He hopes to go into engineering in January 2022 and then be able to really start production in 2023. The potential is huge, because around 10,000 tons of the required raw material are produced in Germany alone every year. Wacker enthusiastically calculates that the entire polyurethane used in Germany could be replaced with its eco-softfibre...and of course, the more you produce, the cheaper the material becomes for the end user.

If you want to know more about the Görlitz world novelty: Here you go directly to eco-softfibre .

Otherwise - we will keep you up to date on the further developments of the promising company!

Best regards -

Your Jasna